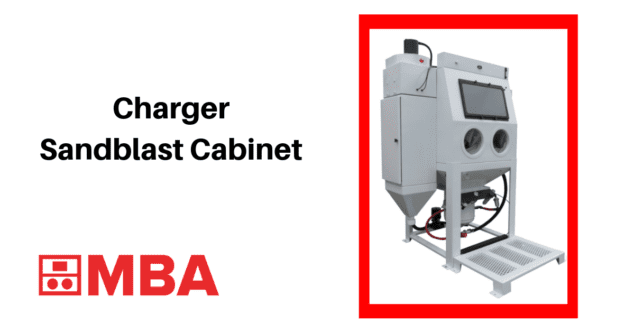

Media Blast’s Charger automotive sandblast cabinet uses direct pressure abrasive delivery and is capable of extended daily operation. This blast cabinet comes standard with a production-level nozzle that works with 25-90 cfm of compressed air per minute. It’s a great machine for anyone in the automotive industry looking to process several parts each day.

The Media Blast & Abrasives Industry Blog: Expert Perspectives

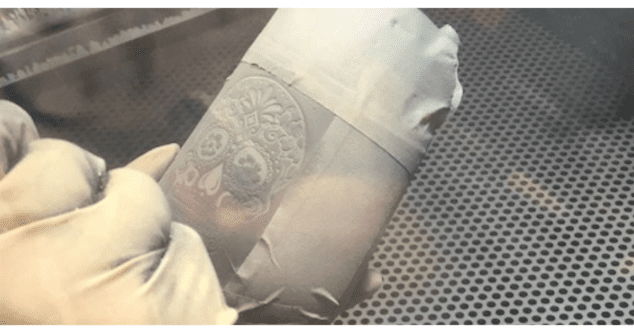

This past weekend Darin Jones and Andy Hromatka, Technical Sales Specialists with IKONICS Imaging, co-hosted a hands-on sandcarving seminar with the team at Media Blast & Abrasive, Inc. in Brea, California.

Automated sandblasting cabinets seem like they’d be the answer for companies looking to reduce labor and increase production volume. We’ve compiled the four most frequently asked questions about cabinet automation to help you to decide if it’s something you can benefit from.

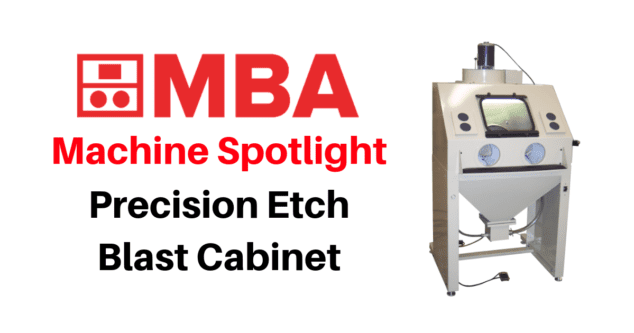

The Precision Etch sandblasting cabinet is a clean, quiet, well-designed micro siphon unit ideal for applications requiring small parts and high production volumes. It is one of three abrasive blasting cabinets designed specifically for proper control and flow of smaller amounts of abrasive (measured in pounds per minute) using all the right abrasive delivery controls. What Are Micro Industrial Sandblasters? These sandblasting cabinets come with large negative pressure dust collectors for clean operation in small spaces and…

A dust collector filter is among the most important components for sandblasting cabinets. Machine footprint combined with Dust Storage Capacity is what created the need for dust collector advancements. Although we’ve made huge strides in innovation, dust collector filter maintenance is still an important factor. Types of Dust Collector Filters: 1st came the Positive Pressure Dust Bag attached to the blower exhaust outlet. These are still used today but only by companies that don’t understand dust…

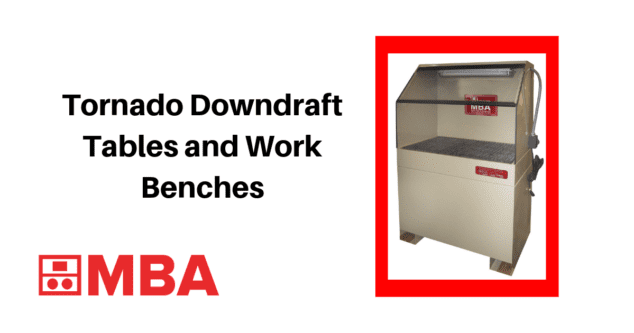

Media Blast & Abrasive’s line of Tornado downdraft work tables is designed for pollution control from grinding, sanding, and deburring normally using a central dust collector. These machines protect the operator and surrounding equipment from free floating debris. Tornado workstation unlike the Tornado Work Bench do not include an internal dust collector, but they do include the collection hopper, hopper attachment outlet for connection to a central dust collector and other great features like lighting,…

Wet blast cabinets have been around for a very long time. Although dry blasting almost made wet cabinets obsolete, more and more applications today require wet blasting because it eliminates the frictional heat that can damage delicate parts and permits iron free blasting. A few wet blasting applications include critical plating and painting, chemically clean part surface, no abrasive impregnation into the part surface, and aircraft part cleaning with the least part surface removal.

The most important thing to remember about choosing the right blast cabinet is focusing on your application and not whether the part fits inside the cabinet. That’s why Media Blast & Abrasive manufactures more than 50 models and 170 different cabinets – so we can make the right machine for any application.

Blasting cabinet design are more than an enclosure to contain the blasting operation, a trigger operated paint gun for on and off abrasive delivery and a looped abrasive supply hose down into the abrasive with an entrance hole in the hose.

When you think about using a media blasting cabinet, i.e. sandblasting cabinet, with enclosed containment and recycling abrasive, one of the first things you will find are different types of abrasive deliveries to the blast gun. This post will help to uncover which delivery – wet or siphon or direct pressure – is best for your application.